Bailey & Mackey Ltd

The technology of pressure measurement has changed considerably over our 75+ years of growth and leadership. Always at the forefront, we now offer comprehensive ranges of analogue and digital Pressure Switches, Gauges and Transducers for customers from widely diverse industries.

Careful attention to quality control, R&D and cost efficient manufacture ensures we provide you with the most effective solutions to measurement of gas and liquid processing pressures.

Bailey & Mackey’s range of Bourdon Pressure Gauges is built to the highest standards of workmanship required for such precision instruments. Each individual Pressure Gauge is subject to a series of stringent pressure and calibration tests before despatch.

The maximum pressure that we manufacture to is 700 bar (10000 psi)

- Introduction

Bourdon Tube Gauges consist of a formed tube with one end fixed and the other end free to deflect under pressure. This type of gauge is only available for applications where the material of the tube (e.g. Beryllium Copper or Stainless Steel) is compatible with the fluid in the system

- Applications

Bourdon Tube Pressure Gauges with brass connections and phosphor bronze tubes are suitable for use on air, water, oils and other fluids compatible with these materials. (When used on steam a syphon should be fitted and filled with water prior to use). Pressure Gauges manufactured in stainless steel are for use with corrosive fluids, in corrosive environments or where food/hygiene requirements demand a higher specification.

- Vacuum

All sizes of Bourdon Tube Pressure Gauges can be supplied for indication of vacuum relative to atmospheric pressure.

Gauges calibrated 0–30in Hg or 0–760mm Hg will, normally, have their pointers moving clockwise on increasing vacuum. Gauges calibrated 0–1 bar have their pointers moving anti-clockwise. Absolute Pressure Gauges are not included in the Bailey & Mackey range.

- Combined Pressure And Vacuum

Gauges indicating of both pressure and vacuum in one instrument can are also manufactured.

- Working Pressure

It is recommended that the gauge range should be chosen so that the working pressure is not more than 65% of the maximum scale value for fluctuating pressures or 75% for steady pressures.

- Accuracy

Bailey & Mackey Bourdon Tube Pressure Gauges are normally supplied to the accuracy laid down in BS EN 837. The maximum pressure that we manufacture to is 700 bar (10000 psi)

|

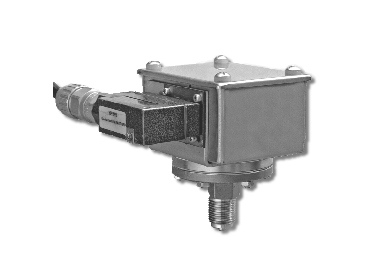

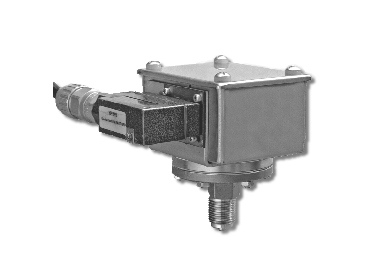

Bailey & Mackey’s range of Pressure Switches is built to the highest standards of workmanship required for such precision devices, with our Series 5000 also offering ATEX approved micro-switch enclosures. Each individual Pressure Switch is subject to a series of stringent pressure and calibration tests before despatch.

The maximum pressure that we manufacture to is 700 bar (10000 psi)

- Bailey & Mackey Pressure Switches

measure pressures relative to atmospheric pressure and are divided into three main groups, each group being based on a different measuring principle. The majority of our pressure switches have a SPDT micro-switch fitted, including versions in ATEX approved housing, but where double pole switching is required, we can supply a range of pressure switches fitted with a DPDT micro-switch.

- Diaphragm Switches

consists of either a corrugated metallic diaphragm or a synthetic rubber diaphragm. Metallic diaphragms are more versatile as the diaphragm can be treated to meet the majority of chemical applications, where as synthetic rubber diaphragms are limited to the compatibility of the synthetic rubber. The maximum pressure that diaphragm switches normally operate is 42 bar but they can be overload protected to 200 bar. Diaphragm pressure switches can also be set to switch in vacuum.

- Piston Switches

consists of a piston that has a o’ring seal that is either mounted on the piston or in the body. Piston switches are normally used where the pressure is above that of diaphragm switches. Piston switches should not be used on gasses due to the inherent high friction that an o’ring has especially when pressure is not applied for a period of time. Piston switches are for high-pressure applications of up to 700 bar.

- Bourdon Tube Switches

consists of a formed tube with one end fixed and the other end free to deflect under pressure and operate an electrical switch. Bourdon tube switches should be used for high pressure gas applications.

Pressure ranges up to 600 bar can be supplied. Bailey & Mackey Pressure Switches can be modified to suit almost any requirement.

|

Intended for use in hazardous areas where an intrinsically safe circuit cannot be used, These pressure switches can be used to monitor or control pressures within a fluid system by either closing or opening an electrical circuit. They consist of a housing containing the pressure sensing mechanism with an external microswitch contained within an ATEX housing.

- Robust and reliable

- Diaphragm operated < 40 bar

- Piston operated > 40 bar

- Wetted parts for use with all fluids

- Fully adjustable set point with optional fully adjustable hysteresis

- Enclosure rating IP67

- ATEX Approved to: CE Ex II2 G (EEx.d.e. IIC. T6)

Pressure Switches – Series 5000

- Maximum Pressure

To ensure long service life select the pressure range as follows:

Dynamic pressure applications Pmax = 75% of range.

Static pressure applications Pmax = 100% of range.

Maximum pressure that can be applied is 125% of pressure range.

- Electrical Rating

5 amp at 250V 50 Hz. For other voltages and currents please consult our technical department.

- Installation

These pressure switches can be mounted directly on the connecting thread. Sealing groves are machined onto the end face of parallel threads for use with sealing washers. A dedicated mounting bracket is available if required.

|